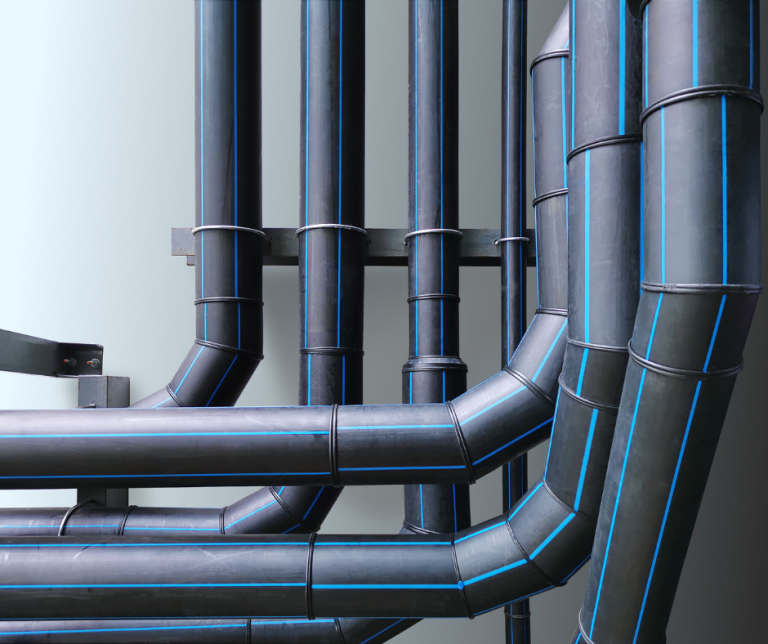

HDPE (High-Density Polyethylene) butt fusion machines are widely applied in various fields and industries. Here are some common applications:

1. Plumbing and Water Supply Systems:

HDPE pipes are used for transporting water in municipal water supply networks, industrial water systems, and agricultural irrigation. The butt fusion technique ensures leak-proof connections for efficient water flow.

For example, in a large-scale municipal water project, HDPE pipes joined by butt fusion machines can provide a reliable and long-lasting water distribution system.

2. Gas Distribution Networks:

They are employed in the installation of gas pipelines to ensure safe and leak-free gas transportation.

A case in point is the expansion of a gas distribution network in a new urban development area, where HDPE pipes fused with butt fusion machines meet the strict safety standards for gas supply.

3. Industrial Process Piping:

In industries such as chemical, petrochemical, and pharmaceutical, HDPE pipes are used for transporting various fluids and chemicals. The butt fusion process guarantees the integrity of the piping system.

For instance, in a chemical plant, HDPE butt fusion connections are used for piping corrosive substances without the risk of leaks.

4. Sewage and Drainage Systems:

HDPE pipes are suitable for sewer and drainage applications, and the butt fusion method creates strong and sealed joints.

Imagine a large-scale sewage treatment plant where HDPE pipes joined by butt fusion machines handle the flow of wastewater effectively.

5. Geothermal Heating and Cooling Systems:

These machines are used to install HDPE pipes for geothermal energy transfer.

In a residential or commercial geothermal system, the precise fusion of HDPE pipes ensures optimal heat exchange and system performance.

Overall, the application of HDPE butt fusion machines is crucial in creating durable and leak-free piping systems in a wide range of infrastructure and industrial projects.