When choosing the welding machines for HDPE pipes and steel pipes, we have to clarify the different demands for the two materials. The butt fusion welding machine is used for HDPE pipes and the MIG/ARC welder is applied for steel pipes.

HDPE and steel are popular materials/fittings for piping. However, one material is better than the other. When assessing HDPE and steel pipe, learn why HDPE is the superior choice.

Table of Contents

Understanding HDPE Pipe

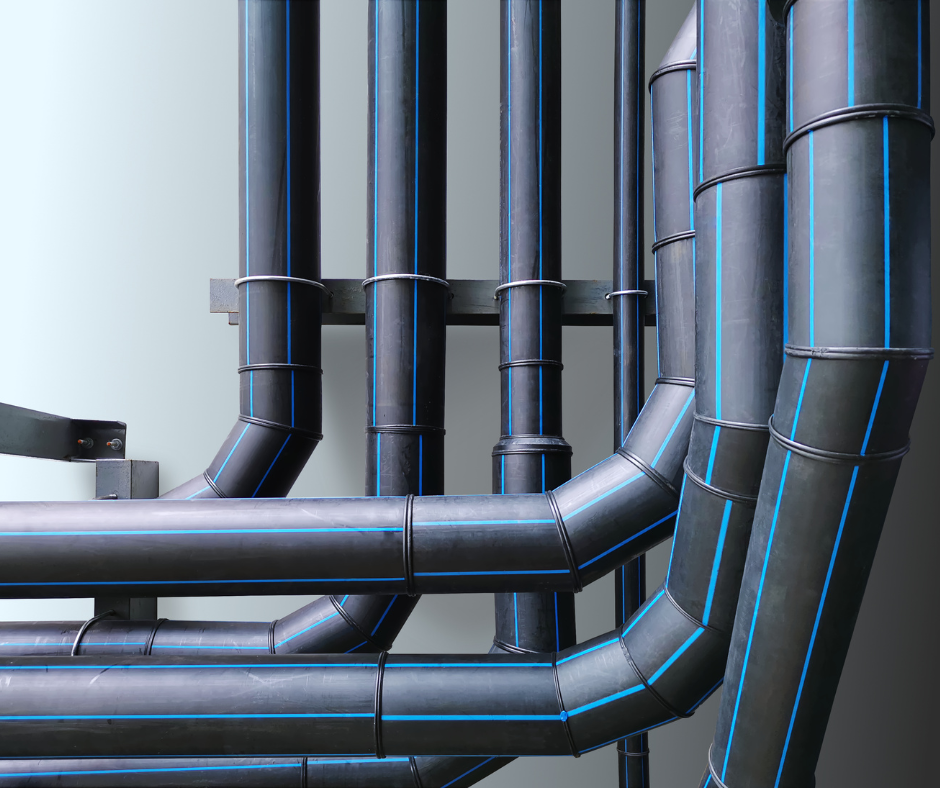

HDPE pipe consists of flexible plastic made of thermoplastic high-density polyethylene. Its common use is transferring low-temperature fluid and gas.

High-density polyethylene is a synthetic polymer made from petroleum. The pipe’s molecular bond makes it right for high-pressure pipelines for applications like carrying hazardous waste, stormwater, and gases. Typical HDPE pipe applications include industrial, agricultural, construction, and mining. However, you’ll find this pipe in various other industries.

Understanding Steel Pipe

Steel pipe is long, hollow tubing useful for many applications. Its versatility makes it one of the steel industry’s top-produced items. Due to its high strength, people use steel pipes for structural, manufacturing, and transportation purposes.

Like HDPE pipe, galvanized steel pipe is popular for transporting liquids and gas. In fact, galvanized steel pipe was the most common pipe for water supply lines. However, the corrosive nature and limited lifespan decreased steel pipe popularity.

Why HDPE Is the Best Choice

When comparing HDPE and steel pipe, HDPE is superior because it’s lightweight, corrosion resistant, and has a long lifespan.

HDPE pipe has solid, straight, or flexible coiled lengths, and the lightweight materials are easy to transport. Unlike steel pipe, HDPE isn’t heavy, nor does it require heavy equipment for installation.

Although steel pipe has a zinc coating, galvanized steel eventually corrodes and can harm drinking water and other substances inside the pipe. Fortunately, HDPE pipe is chemical and corrosion-resistant, posing no threat to internal materials.

Additionally, longevity is a major component of piping. Galvanized steel pipe has a lifespan of 40 to 50 years. However premature corrosion can decrease its life. On the other hand, HDPE pipes should last 50 to 100 years without external forces affecting the material.