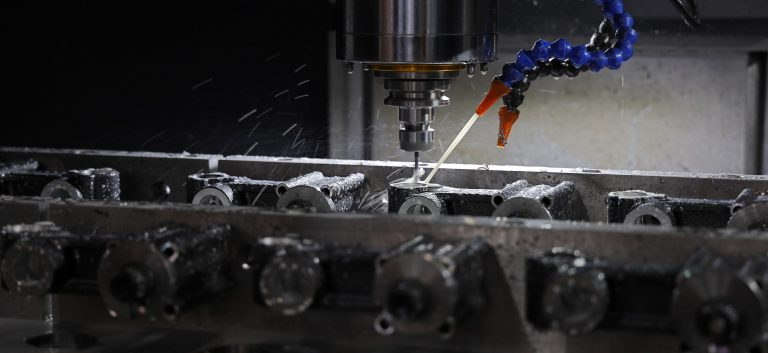

The working principle of the hot melt butt welding machine is as follows:

First of all, the hot melt butt welding machine heats the ends of the two pipes or fittings to be joined to a specific temperature. This is usually achieved through heating elements or a heating plate. The heating process is carefully controlled to ensure that the material reaches the appropriate melting point without overheating or underheating.

Once the ends are heated and melted to the desired state, the machine quickly brings the melted ends together and applies pressure. The pressure helps to fuse the molten material and create a seamless joint.

During the joining process, the machine maintains the pressure for a certain period of time to allow the material to cool and solidify, forming a strong and durable connection.

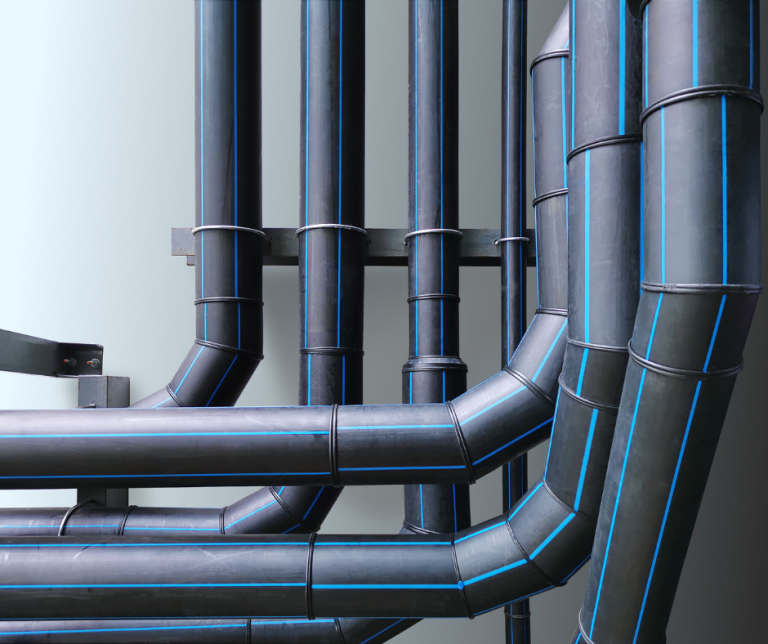

For example, in the construction of plastic pipelines for water supply or gas transportation, the hot melt butt welding machine is commonly used to ensure the integrity and leak-proof nature of the pipeline connections. Another example could be in the manufacturing of plastic components where precise and reliable joints are crucial for the performance and quality of the final product.